Koch-Chemie Polishing System

The development of new scratch-resistant paint systems is progressing, whilst car manufacturers keep coming up with new challenges related to polishing compounds` power and efficiency. The increased use of orbital machines such as the Rupes Big Foot for defect correction has also contributed to the evolution of our polishing system.

The product development aims to increase the level of cut for all of our polishing compounds whilst simultaneously maintaining a high level of gloss. After thorough research and testing, our R & D team has successfully achieved this goal. Have a read here to learn more about the development process.

Polishing compounds and pads – a complementary system

It is not enough to select an excellent polishing compound to achieve great polishing results. Besides, the right machine choice, a great deal of experience in application, polishing pads quality, etc. are just as important.

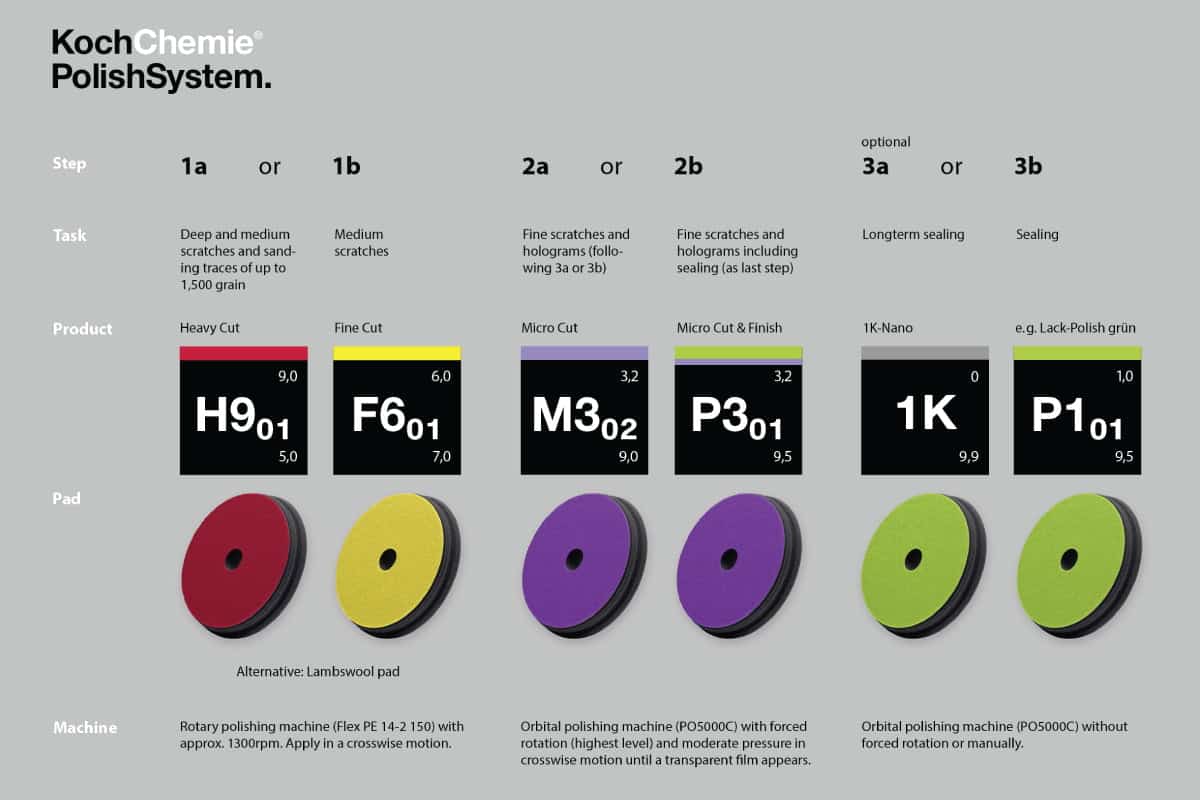

In cooperation with a polishing pads manufacturer, we have worked on and come up with the finest quality pads matching every polishing compound. Our new partner handles all steps production involves, from chemicals development to assembling – everything is made in Germany. With the new system, ideal results can be achieved even faster in our simple two-step process.

We have made our pads thinner by reducing their height to 23mm, which resulted in reduced torsion forces, improved handling, and maximum stability during polishing. The unique foam material produced specifically for Koch-Chemie has a special density, which ensures long-lasting compression resistance and enables polishing pads to retain their shape. Optimal reticulation along with the specific number of cells contributes to improved abrasiveness and excellent hygiene factors.

The milling edge gives the pads increased flexibility to better fit around contours. The fleece matching the color code of the polishing compounds allows to distinguish between the uniform black pads and offers users even more reliability. The new color-coordinated dust-free single packaging of the pads ensures you’ll make the right choice.

Comments

Comments

Related Articles

Related Articles

Polish Production Process

Not only does a good polishing compound produce a high gloss level, but also protects the surface from UV rays, chemicals, and other external influences. Professional car detailers appreciate...

How Do We Develop Our Compounds?

Your car’s finish is what makes the first impression and lets people know how much you value and appreciate your car. As such, it has got to be as smooth and sleek as possible. But it doesn’t take a...

0 Comments